Types of Sewing Machines When it comes to sewing machines, there are several types to choose from. Each type has its...

Setting Up a Factory to Manufacture High-Quality Computerized Embroidery Machines: A Comprehensive Guide

-

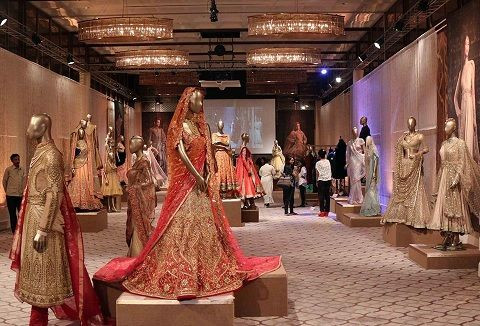

Identify the Market: Conduct market research to identify the demand for computerized embroidery machines in the market. This will help you determine the type of machines you need to manufacture and the features that are in demand.

-

Develop the Product Design: Once you have identified the market demand, it's time to develop the product design. Hire experienced engineers to design the machines with the latest technology and features that meet the requirements of your target market.

-

Procure the Parts: Once the product design is finalized, you need to procure the parts required to build the machine. Ensure that you source high-quality parts that meet the required standards and specifications.

-

Assemble the Machine: The next step is to assemble the machine. This requires experienced technicians who have the necessary skills to put together the various components of the machine.

-

Test the Machine: Once the machine is assembled, it needs to be tested thoroughly to ensure that it meets the required quality standards. Conduct rigorous testing to check the functionality, durability, and performance of the machine.

-

Quality Control: Implement a quality control process to ensure that each machine manufactured meets the required quality standards. This includes inspecting each component, testing the machine before shipping, and ensuring that it meets the specified requirements.

-

Factory Setup: Finally, you need to set up a factory to manufacture the machines. This requires a significant investment in infrastructure, including space, equipment, and skilled labor. The factory should be designed to optimize the manufacturing process, including assembly, testing, quality control, and packaging.

In summary, manufacturing and factory setup for computerized embroidery machines requires a significant investment in both capital and expertise. To ensure high-quality products, it's essential to hire experienced engineers, technicians, and skilled labor, source high-quality parts, conduct rigorous testing, and implement a robust quality control process. With the right approach, you can establish a successful factory for manufacturing top-quality computerized embroidery machines.

The details of the equipment, software, employees, salaries, and total cost required for setting up a factory to manufacture computerized embroidery machines will vary depending on the scale and complexity of the operation. However, here is a general overview of the key components that would be required:

- Equipment: The key equipment required for setting up a factory to manufacture computerized embroidery machines would include:

- CNC machines for cutting metal parts

- Laser cutting machines for cutting acrylic or plastic parts

- Metal bending machines for bending metal sheets

- Welding machines for joining metal parts together

- Surface grinding machines for finishing metal parts

- Drilling machines for making holes in metal parts

- Industrial sewing machines for testing and calibration

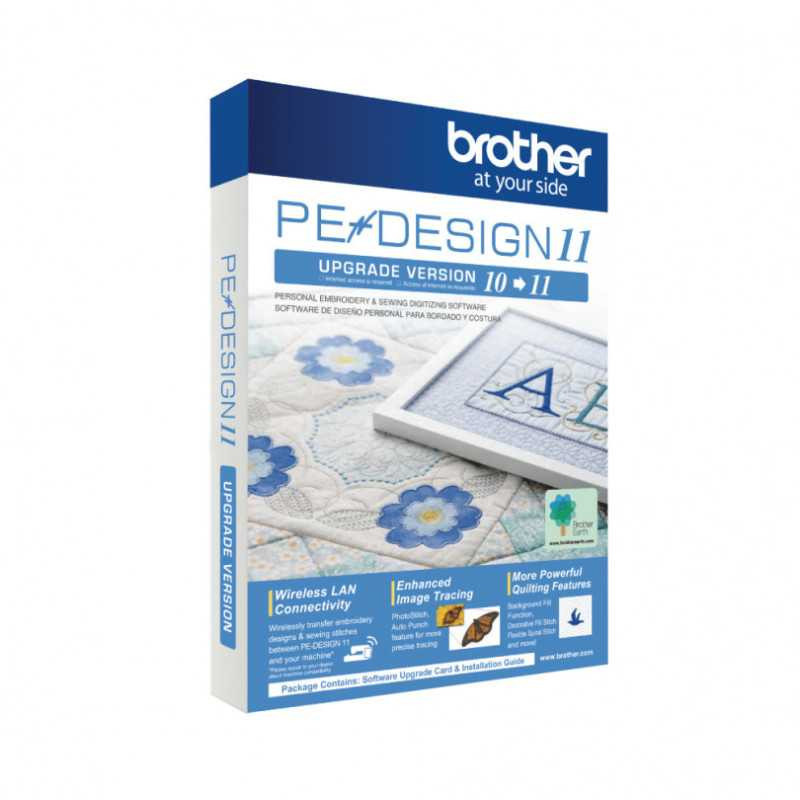

- Software: In addition to the physical equipment, a factory would also require software for designing the machines, managing production, and controlling the machinery. This would include:

- Computer-Aided Design (CAD) software for designing the machines

- Computer-Aided Manufacturing (CAM) software for programming the CNC machines

- Enterprise Resource Planning (ERP) software for managing production and inventory

- Quality Control (QC) software for monitoring the manufacturing process and ensuring product quality

- Employees and Salaries: Setting up a factory to manufacture computerized embroidery machines would require a team of skilled employees, including:

- Engineers for designing the machines

- Technicians for assembling and testing the machines

- Quality control specialists for monitoring the manufacturing process and ensuring product quality

- Sales and marketing professionals for promoting and selling the machines

Salaries for these employees would depend on their level of experience and qualifications, as well as the prevailing labor market rates in the location where the factory is located.

- Total Cost: The total cost of setting up a factory to manufacture computerized embroidery machines would depend on a range of factors, including:

- The size and complexity of the factory

- The number of employees required

- The cost of equipment and software

- The cost of raw materials and supplies

- The cost of utilities and rent

The total cost could range from a few hundred thousand dollars for a small factory to several million dollars for a larger, more complex operation.

In summary, setting up a factory to manufacture computerized embroidery machines would require a range of equipment, software, skilled employees, and a significant investment of capital. The specific requirements and costs will depend on the size and complexity of the operation, but with the right approach, it is possible to establish a successful manufacturing operation for top-quality computerized embroidery machines.

Leave a comment